Why buy a used safe?

If properly maintained and serviced these safes will last for decades. The barrier

material that is enclosed between the heavy inner and outer steel plates does not

degrade and is as strong today as when it was built. We inspect, clean and re-lubricate

the boltwork and locking mechanisms to ensure many years of continued service. If

necessary, we replace the locks with new ones of the same grade. We also sand and

repaint the exterior and interior surfaces. We adhere to the highest standards to

provide the best quality product.

A new high security safe today with torch and tool resistance can easily start at $15,000

plus, and the highest level of security can easily exceed $40,000. Our used TRTL 15x6eq

safes start at $3,200, and the TRTL30x6eq safes start at $3,950.

John Tann is no longer in business and the safes produced by Chubb today, while still

excellent, are not of the same caliber of theft deterrence. While It would still be possible

to build safes of the same quality today, the cost to do so is prohibitive. Therefore, safes

today are built to beat a specific test for either 15, 30, or 60 minutes.

Why are these the only safes we sell?

The 1970’s thru the mid 1990’s were the best years of British safe making. The

companies of Chubb and John Tann built the strongest safes on the planet to meet the

demand of businesses and banks that held large amounts of cash. At English Safes we

believe there is still a market for this product, and with our English partner we are proud

of the opportunity to offer it to you.

What makes these safes better or stronger?

When these safes were manufactured the priority was craftsmanship not cost. The

companies of Chubb and John Tann were constantly competing against each other to

build a better and stronger safe. The heavy range of Chubb bankers’ safes were built

using massive slabs of copper and aluminum mixed with extremely hard aggregates that

would destroy the hardest drill bits and disc cutters. The two-inch-thick slab of copper in

the door and body dispersed the heat of Oxyacetylene and Arc Air slicers, making it

impossible to start a cut with these torches.

John Tann’s barrier material Adamantium (security concrete) was mixed with plasticizers

and iron shot and poured in an ultra-fluid state, surrounded a slab of aluminum. All this was embedded within multiple steel grids with extra protection of stainless and

manganese steel in the bolt locking areas.

So why do we only sell Chubb and John Tann safes. Not because they were the best, but

because they still are.

Brochures

Chubb Trident

Chubb Resolute

Chubb Conqueror

Chubb Bankers Treasury

Resources

Tann Jewelers Safe Testing | Tann Safe Brochure

Model Details

Chubb – Bankers Treasury [pdf]

Chubb – Resolute [pdf]

Chubb – Trident [pdf]

Media

Video documentation of how modern, store bought premium safes offer a minimal level of security

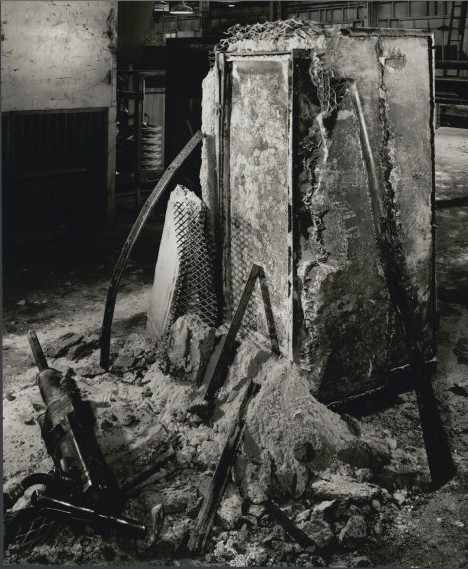

The below photos are the aftermath of an unsuccessful two day attack on a John Tann Mark 4 Grade three Bankers Safe.